A Comprehensive Guide to Electrical Maintenance Management for Brazilian Companies

fp

Understanding Electrical Maintenance Management

Electrical maintenance management is a crucial aspect for companies in Brazil, ensuring the smooth operation of electrical systems and minimizing the risk of unexpected failures. This comprehensive guide will explore the various components of effective electrical maintenance and how Brazilian companies can implement robust strategies.

The Importance of Regular Inspections

Regular inspections are at the core of effective electrical maintenance management. By conducting thorough checks, companies can identify potential issues before they escalate into costly problems. Inspections should include checking all electrical equipment, wiring, and safety systems to ensure they meet industry standards and regulations.

Preventive vs. Predictive Maintenance

Understanding the difference between preventive and predictive maintenance is essential. Preventive maintenance involves routine tasks designed to reduce the likelihood of equipment failure, such as cleaning, lubrication, and part replacements. On the other hand, predictive maintenance uses data analysis and monitoring tools to predict equipment failures before they occur, allowing for timely interventions.

Developing a Maintenance Plan

Creating a comprehensive maintenance plan is critical for Brazilian companies to manage their electrical systems effectively. The plan should outline specific tasks, schedules, and responsibilities, ensuring that all team members understand their roles in maintaining the system's integrity.

Key Components of a Maintenance Plan

A well-rounded maintenance plan should include:

- Inventory Management: Keep track of all electrical components and their service history.

- Training: Ensure all staff are adequately trained in maintenance procedures and safety protocols.

- Documentation: Maintain detailed records of inspections, repairs, and maintenance activities.

Utilizing Technology in Maintenance

Incorporating technology can significantly enhance electrical maintenance management. Tools such as thermal imaging cameras, circuit analyzers, and maintenance management software can provide valuable insights into system performance. These technologies enable companies to perform more accurate diagnostics and streamline maintenance processes.

The Role of Safety in Electrical Maintenance

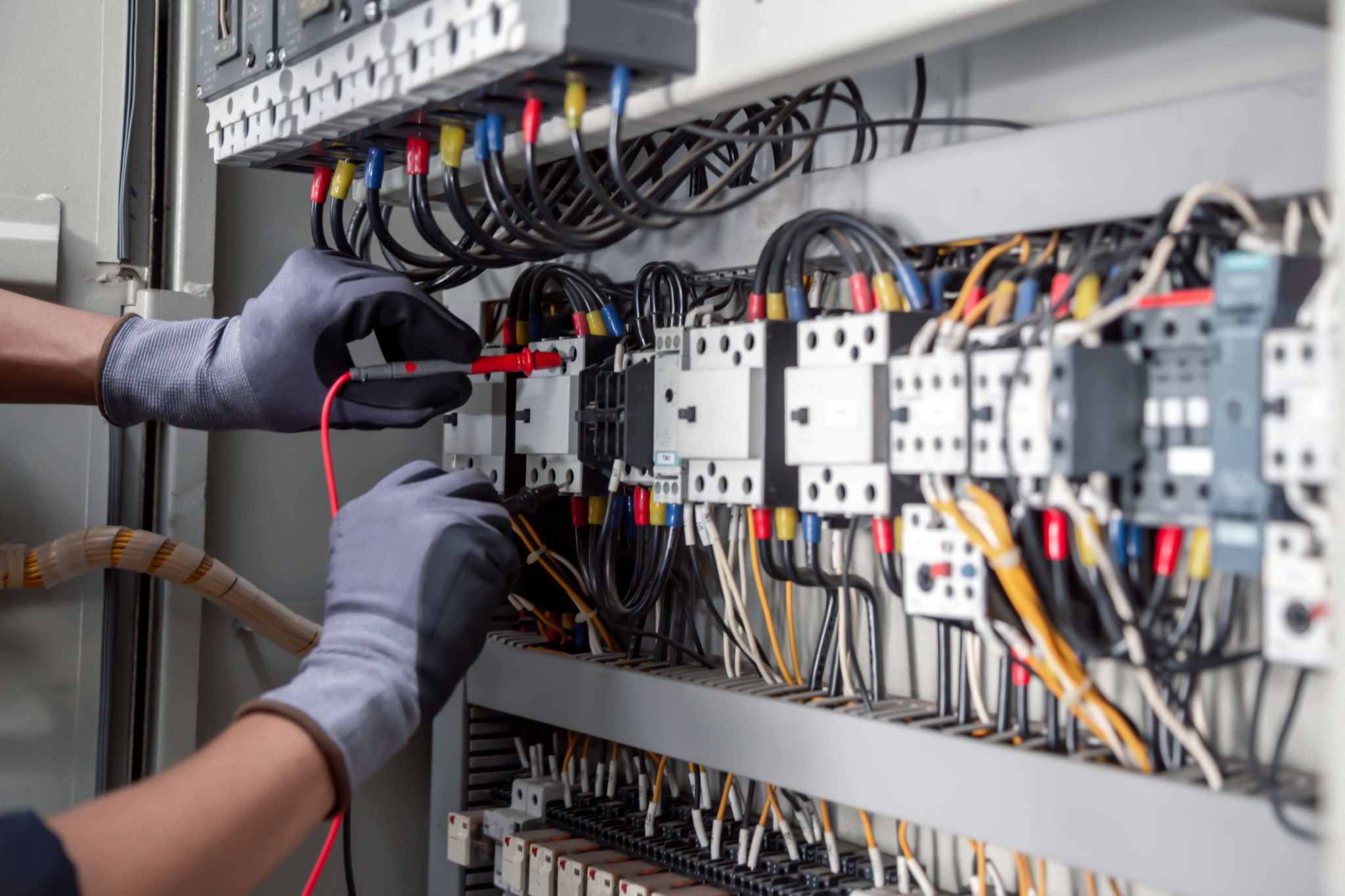

Safety is paramount in electrical maintenance management. Companies must adhere to strict safety standards to protect employees and equipment. This includes providing appropriate personal protective equipment (PPE) and enforcing safety protocols during all maintenance activities.

Compliance with Brazilian Regulations

Brazilian companies must also ensure compliance with local regulations regarding electrical systems. These regulations are designed to protect both workers and consumers by establishing clear standards for electrical installations and maintenance practices.

Conclusion: The Benefits of Effective Maintenance Management

By implementing a comprehensive electrical maintenance management strategy, Brazilian companies can enjoy numerous benefits. These include increased system reliability, reduced operational costs, and enhanced safety. Ultimately, a proactive approach to maintenance can lead to improved productivity and a stronger competitive position in the market.