Electrical Maintenance Scheduling: Best Practices for Brazilian Companies

fp

Introduction to Electrical Maintenance Scheduling

Electrical maintenance scheduling is a crucial component of ensuring the safety and efficiency of operations within Brazilian companies. By adhering to a well-developed schedule, businesses can prevent unexpected downtimes, reduce repair costs, and enhance the longevity of electrical systems. This post aims to guide companies through best practices for creating an effective electrical maintenance schedule.

Understanding the unique challenges and opportunities in Brazil's industrial landscape is key to developing a robust maintenance plan. Companies must consider factors such as local regulations, climate conditions, and the availability of skilled technicians.

Assessing Your Electrical Systems

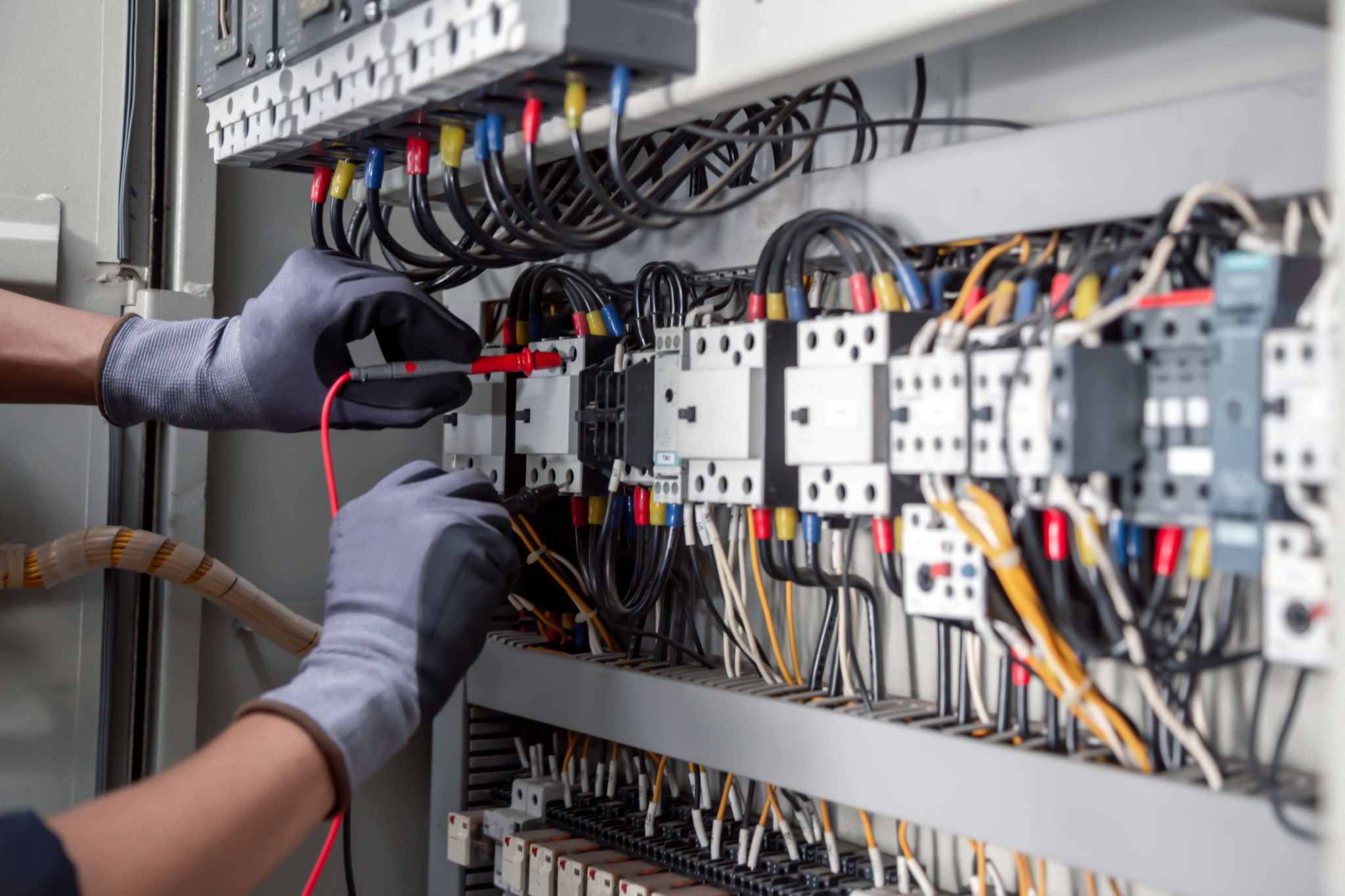

Before creating a maintenance schedule, it is essential to perform a comprehensive assessment of your electrical systems. This involves identifying critical components, understanding their operational demands, and determining their maintenance needs. A detailed inventory of all electrical assets should be compiled, including information on their age, condition, and manufacturer recommendations for maintenance.

Regular inspections should be part of this assessment process, allowing companies to identify potential issues before they escalate into costly problems. Incorporating predictive maintenance technologies, such as thermal imaging or vibration analysis, can also provide valuable insights into equipment health.

Developing a Maintenance Schedule

Once a thorough assessment has been completed, the next step is to develop a maintenance schedule that aligns with the operational requirements of the company. This schedule should include both preventive and corrective maintenance activities, ensuring that all aspects of electrical systems are covered.

Preventive maintenance tasks, such as cleaning, lubrication, and tightening connections, should be scheduled regularly to avoid unexpected failures. In contrast, corrective maintenance should be planned based on the condition monitoring data and historical performance of the equipment.

Implementing the Schedule

Effective implementation of an electrical maintenance schedule requires coordination and communication across various departments. It is crucial to assign clear responsibilities, allocate necessary resources, and ensure that all team members are trained in the latest procedures and safety protocols.

Utilizing computerized maintenance management systems (CMMS) can enhance schedule implementation by providing real-time data, tracking work orders, and facilitating communication among teams. These systems can also help ensure compliance with local regulations and standards.

Monitoring and Adjusting the Schedule

Continuous monitoring is vital to maintaining an effective schedule. Regular reviews should be conducted to evaluate the performance of the maintenance program, identifying areas for improvement and making necessary adjustments. Feedback from technicians and other stakeholders can provide valuable insights into potential improvements.

Adjustments may involve rescheduling tasks based on equipment performance data or incorporating new technologies that offer more efficient maintenance solutions. Staying informed about industry trends and technological advancements can help companies optimize their scheduling practices.

Conclusion

In conclusion, an effective electrical maintenance scheduling strategy is essential for Brazilian companies aiming to maintain operational efficiency and safety. By thoroughly assessing electrical systems, developing a comprehensive schedule, implementing it effectively, and continuously monitoring progress, businesses can reduce downtime and extend the life of their equipment.

By adopting these best practices, companies can not only improve operational efficiency but also ensure compliance with regulatory standards, ultimately leading to enhanced productivity and profitability.